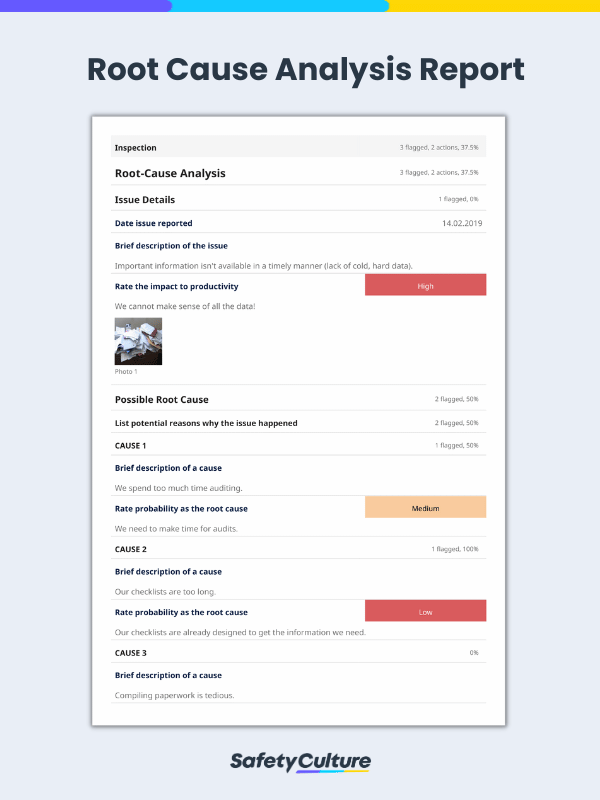

Root Cause Analysis Report

With this root cause analysis report template, you should be able to:

- Define the problem – Clearly state the problem you are trying to solve.

- Collect data – Gather data related to the problem, including when and where it occurred, who was involved, and what happened when the problem occurred.

- Recognize the symptoms – List the observed symptoms and effects of the problem.

- Identify possible causes – Brainstorm all possible causes of the problem, without ruling any out at this stage.

- Analyze the causes – Evaluate each possible cause and determine its likelihood of contributing to the problem. Use tools such as a Fishbone diagram or Pareto chart to help organize and analyze the data.

- Determine the root cause – based on the analysis, determine the fundamental cause of the problem.

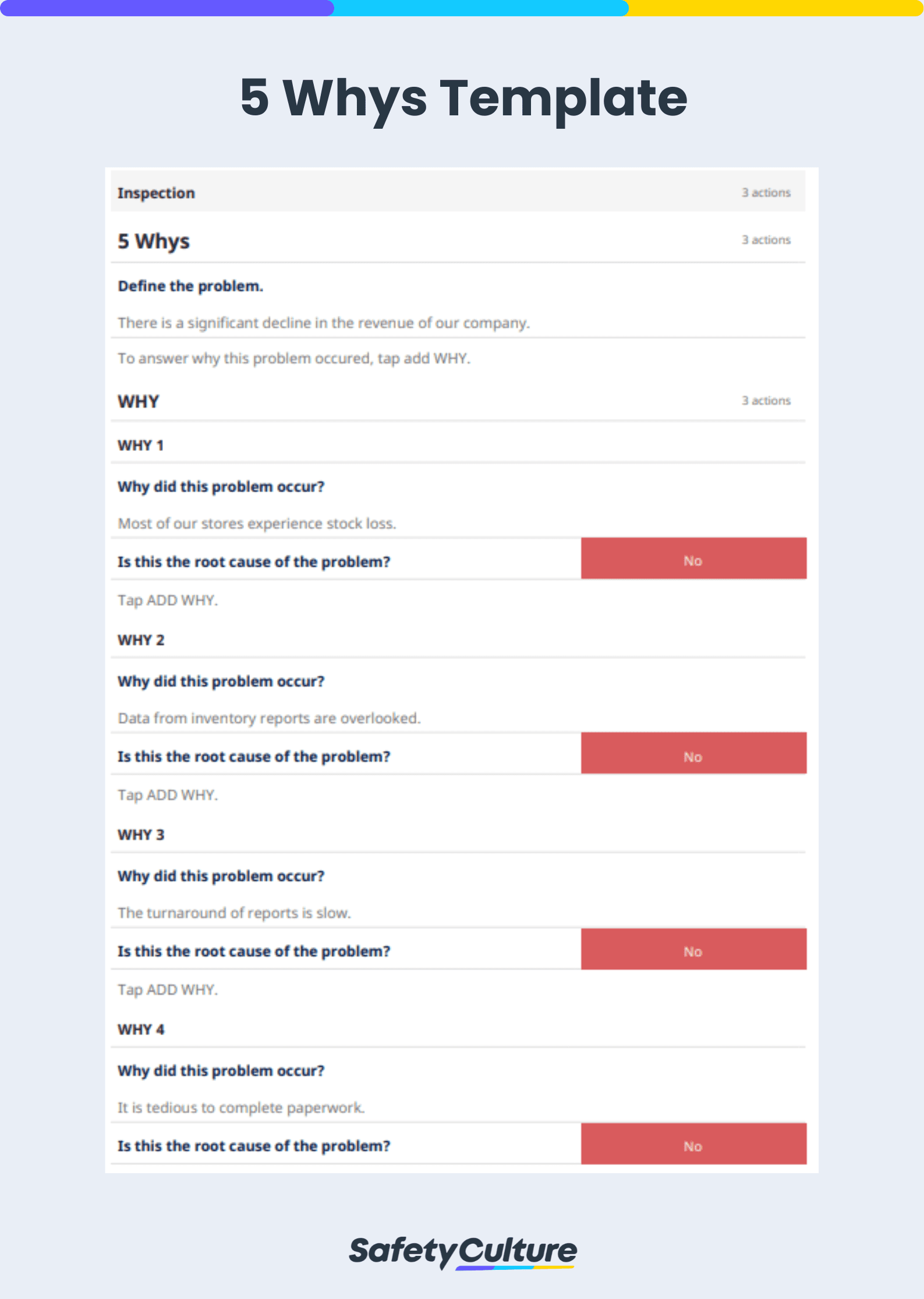

5 Whys Template

The 5 Whys analysis is a strategy for finding a problem’s underlying causes. Identifying the root of the problem entails posing a string of “why” questions—usually five. Using the 5 Whys Template, you may define the issue, explain why it occurred, assess whether this is indeed the primary cause, provide a solution to the problem, and create corrective actions to prevent it from recurring.

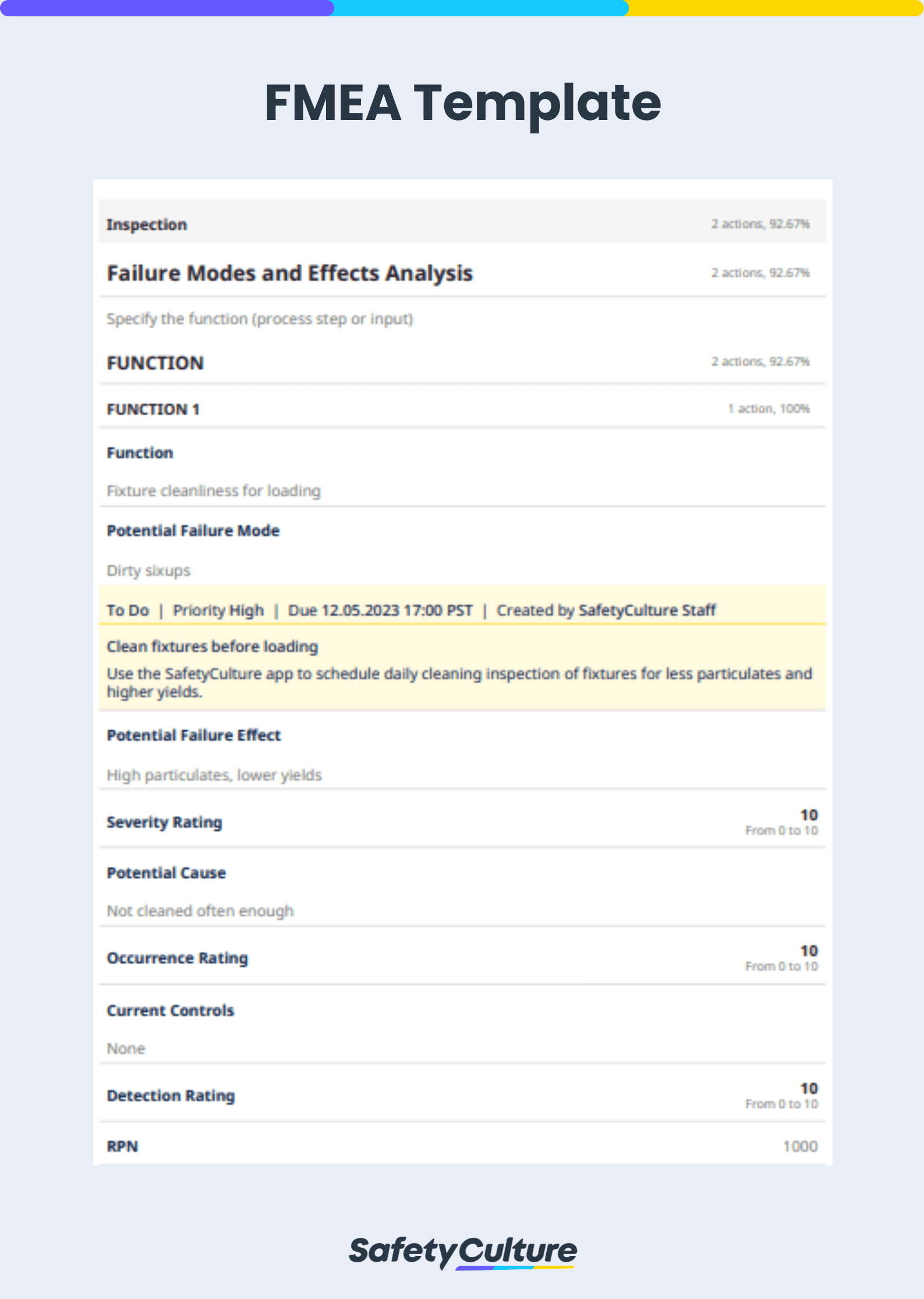

FMEA Template

Failure Mode and Effects Analysis, also known as FMEA, is a powerful tool used to locate and analyze potential failures in a system or process. By determining the effects of these failures and developing strategies to mitigate or eliminate them, FMEA increases the reliability of systems and helps prevent failures from impacting business operations.

This free FMEA template allows you to:

- Specify the function you want to analyze

- Establish the potential failure mode and failure effect

- Determine its level of severity

- State the potential cause

- Identify occurrence rating

- Define current controls

- Record the detection rating

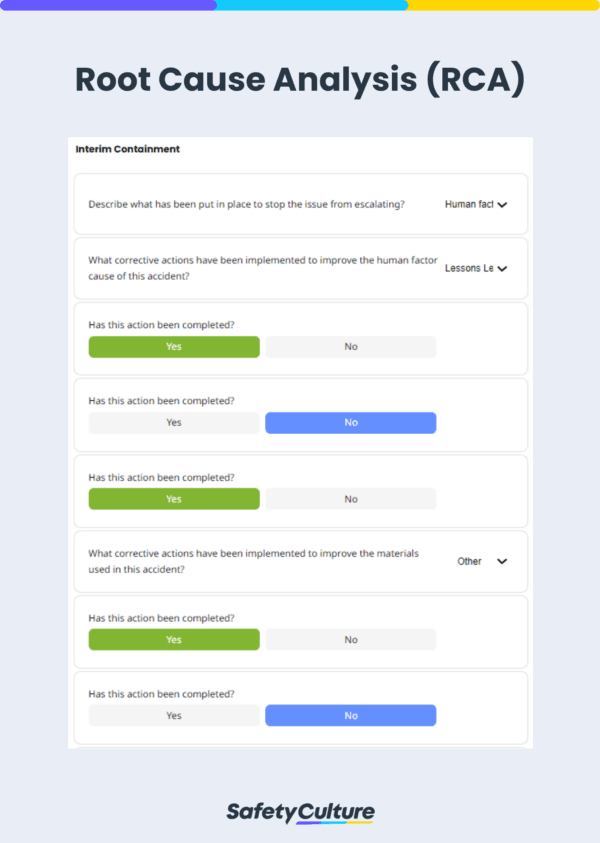

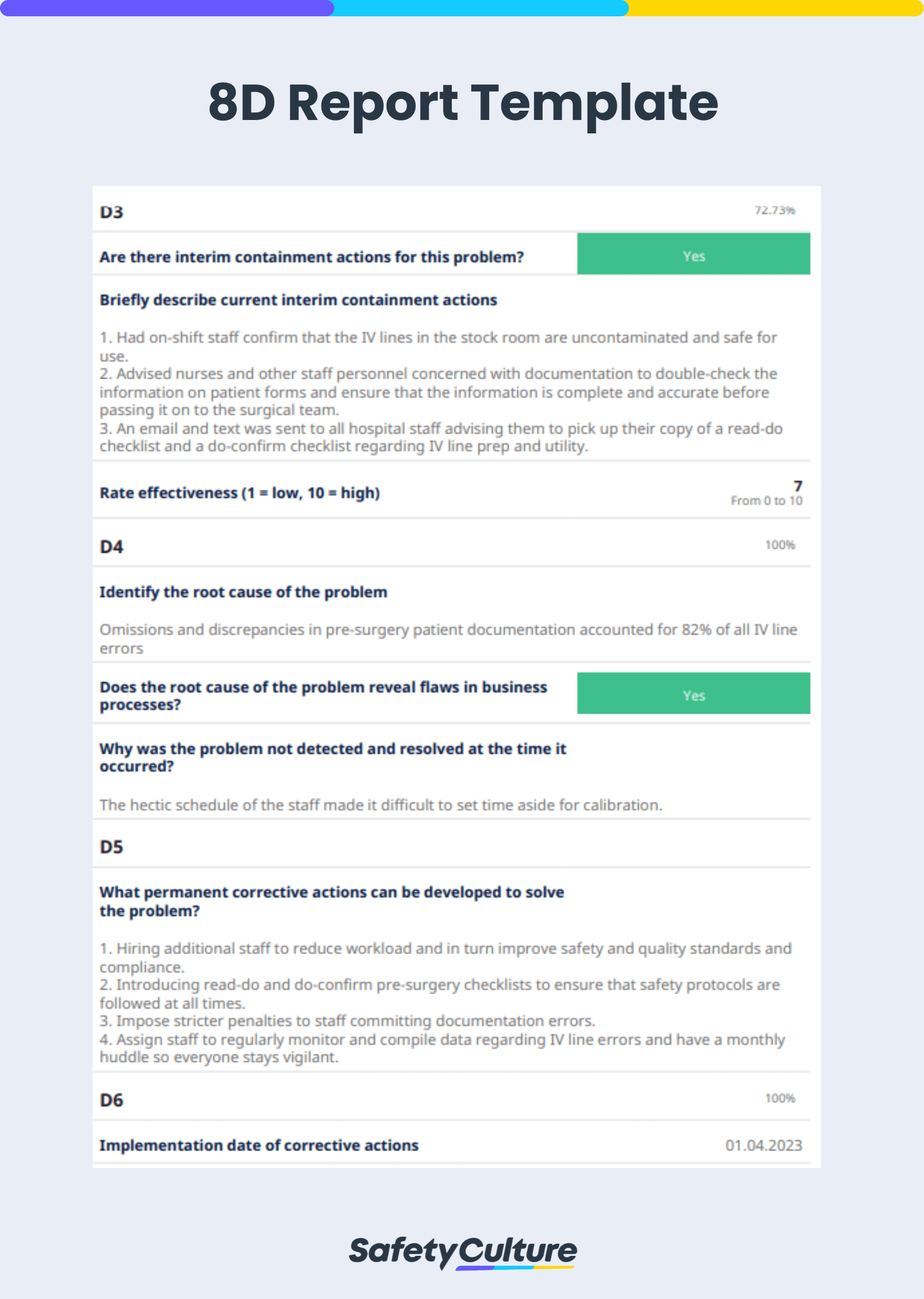

8D Report Template

The 8D (Eight Disciplines) process is a team-based approach that involves eight steps for looking into a problem, determining what caused it, coming up with appropriate solutions, and implementing actions to prevent its recurrence.

The eight steps of the 8D analysis are as follows:

- Establish a team

- Define the problem

- Control the problem

- Identify the root cause

- Develop corrective action

- Implement corrective actions

- Prevent recurrence

- Recognize the team

With this 8D Report Template and by following the eight steps of the process, businesses can develop a solution that not only identifies the root cause of problems and resolves them but also prevents their recurrence.

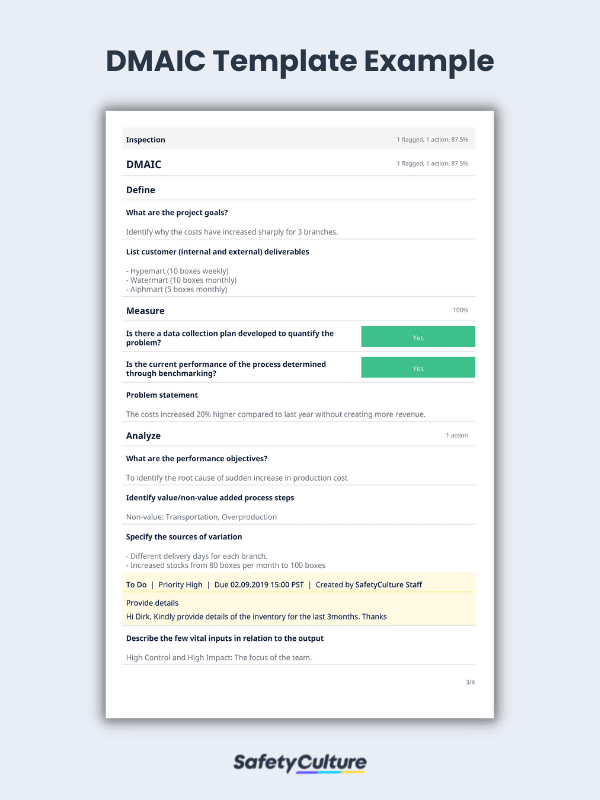

DMAIC Template

DMAIC (Define, Measure, Analyze, Improve, Control) is a structured, problem-solving approach frequently utilized in Six Sigma projects and other process improvement initiatives. Aside from providing users with a place to store the data collected during the analysis, this DMAIC Template also enables them to create corrective actions, attach media-based evidence for increased visibility, and seamlessly share the reports with the team and relevant stakeholders.

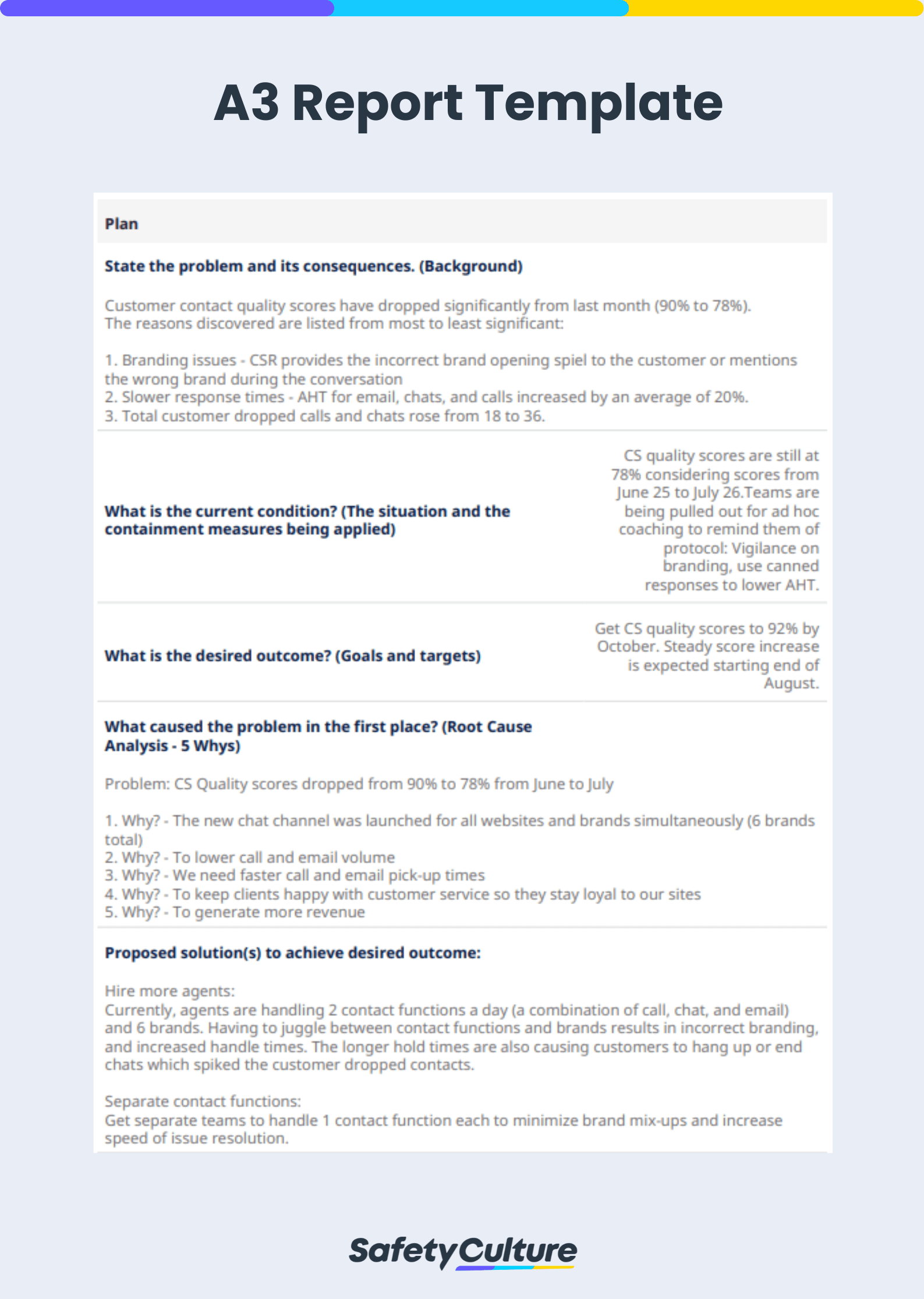

A3 Report Template

A3 Analysis is a problem-solving methodology that originated in Toyota and is now widely used in lean manufacturing and continuous improvement processes. It is named after the A3 paper size, which is used to document the entire problem-solving process on a single sheet of paper.

With this ready-to-use A3 Report Template, you should be able to do the following:

- State the background of the problem

- Define the current situation and put control measures in place

- Specify the goals and desired outcome

- Identify the root cause using the 5 Whys method

- Provide possible solutions to achieve the desired outcome

- Implement actions and solutions

- Measure the effectiveness of implemented solutions

- Verify if the solution helped achieve the desired outcome

- Improve the solutions until the problem is resolved

Jaydee Reyes